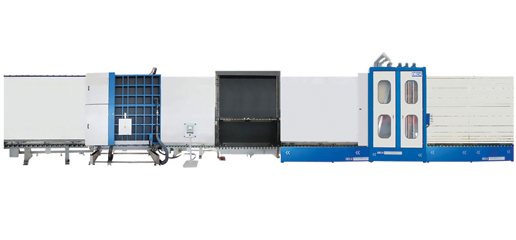

Main feature: 1. Advanced Germany technology, main components adopt international famous brand, reliable performance, powerful function. Can produce double unit, LOW-E unit, extended unit, shaped unit, stepped unit, triple unit and so on 2. The line adopts air cushion working mode, environmental-friendly, better glass protection, best solution for high-level glass processing 3. This line adopts online gas filling system, high speed & efficiency, better gas filling effect 4. All electrical equipment and software adopts Germany Siemens original control system, humanization design, convenient operation, professional design, reliable performance 5. Safe and reliable buffer section and induction system connected with whole machine monitor glass 6. Friction drives the roller wheels, steady transmission, little wear to roller wheels. 7. Automatic identification of glass coating side, so as to control brush rotate speed and wash different kind of glass 8. Adopt professional Low-E washing brushes, which can insure the steady rotary of brushes. 9. Separate washing and rinsing cycle system, environmental protection & energy conservation; special air-knife design guarantees soonest drying effect. 10. Adopt advanced frame mounting and assembly system, frame positioning precisely. 11. The conveyor before pressing robot has glass thickness and frame width automatic identification system, automatic detection, and adjusts the pressing pressure and distance automatically to guarantee the precise assembly. 12. The pressing adopts Germany technology: unique vacuum system can ensure the reliable& steady suction of different size of glass, Guide screw and linear guide servo control system can ensure the precision location and assembly.

Main Technique Parameter:Glass processing dimension: once press min. 190×350mm Max. 2700×3500mm Twice press max. 2700×5000mm Glass processing type: common glass and coating glass Insulating glass thickness: 12-60mm Single glass thickness: 3-15mm Power supply: 380V/ 220V 50HZ Voltage range of fluctuation: + 6%-10% Control voltage: 24V—DC Electrical control system: Siemens PLC Environment temperature: 15℃ -35℃, As per DIN 40040 Relative air humidity: ≤75%, As per DIN 40040 Working height: 500±20mm Angle of inclination: 6 degree Compressed air: 6.5 bar Water supply: min. 4.5bar Distance from glass edge to frame: adjustable from 2 to 20mm Conveyor speed:V=48m/min Working direction: left—right or right—left Tilting table: Height 850±20mm Bearing: max. 1000kg & 250kg/m Stepped IG: vertical distance 2-50mm Horizontal distance: 0-200mm Total power: 51.77 KW Total weight: 8200KG